HOME | REVERSE OSMOSIS | INDUSTRIAL REVERSE OSMOSIS SYSTEMS

Reverse osmosis water filters - iwe range

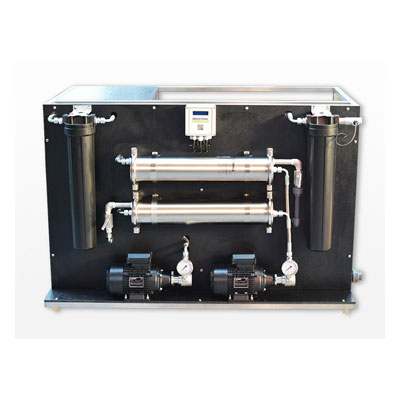

IWE COMPACT RANGE

Compact range RO water filters.

Flow rates up to 150 lph

IWE COMPACT IBC RANGE

Compact IBC range RO water filters.

Flow rates up to 150 lph

IWE PRO RANGE

IWE PROMAX 4 RANGE

Promax 4 range RO water filters.

Flow rates from 2000 lph to 3500 lph

IWE PROMAX 8 RANGE

Promax 8 range RO water filters.

Flow rates from 4300 lph to 12,000 lph

IWE DUPLEX RANGE

IWE TWIN PASS RANGE

Reverse Osmosis Q&A’s

Modular industrial pre-treatment unit showing duplex carbon filter, duplex softener and IWE PRO reverse osmosis filter.

Initially, the incoming water will require filtering through a range of pre-filters before being past to the RO unit.

The purpose of this is initial filtration stage (which is referred to as pre-treatment) includes some of these key benefits :

- Pretreatment such as a carbon filter can remove chlorine, which can damage reverse osmosis membrane(s).

- Pretreatment delivers a consistent feed to your reverse osmosis filtration unit, ensuring stable and accurate water quality.

- Pretreatment extends the overall efficiency of your treatment plant and maximises its operational lifecycle.

Once through the pretreatment stage, the incoming water feed next passes onto the reverse osmosis stage. A correctly installed and configured Reverse Osmosis water filter is capable of rejecting a whole host of contaminants including :

- Sodium

- Sulphate

- Calcium

- Potassium

- Nitrate

- Iron

- Zinc

- Mercury

- Phosphate

- Lead

- Magnesium

- Nickel

- Fluoride

- Chloride

- Manganese

- Cyanide

- Arsenic

- Aluminium

- Copper and many more.

The rejected water (referred to as concentrate) can then either be sent direct to drain, or partially recycled back through the RO filter.

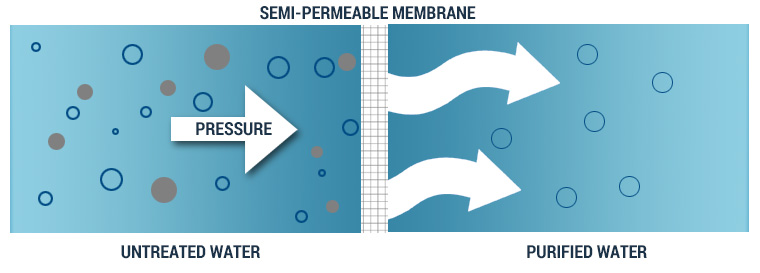

Simplified example of untreated water passing though a membrane

Quite simply, producing RO water involves using pressure to force water through a semi-permeable membrane in order to purify it.

With an industrial Reverse Osmosis system, feed water is pumped at high pressure through either single or multiple reverse osmosis membranes. These membrane(s) are constructed from a single polyester core with an outer spiral wound semi-permeable membrane. It is this membrane which allows microscopic water molecules to pass through. The membrane will reject any larger particulates such as suspended solids, bacteria, chemicals etc.

The rejected water (the concentrate) is either passed direct to drain or optionally reused or recycled. Water which has passed through the membrane (the permeate) can then either be :

- Passed directly on for use in your application

- Placed in a holding tank for use when required

- Moved onto another stage for additional treatment, referred to as polishing.

A correctly configured reverse osmosis water filter is capable of removing over 99% of impurities from feed water.

Low pressure 4040 reverse osmosis membrane

Unfortunately reverse osmosis production will create waste water to degree. A number of factors can influence how much water is lost during the production process. There are also a number of ways to reduce the amount of waste.

Continued development of membrane technologies has dramatically reduced waste water in RO production. This coupled with recovery and recycling techniques means that we can further minimise waste water production.

Some factors that contribute to wastewater include :

- The quality and age of the ro membranes

- The pressure of the incoming feed to the membrane(s)

- The level of impurities within the feed water

- The temperature of the feed water

Membrane Quality

Industrial Water Equipment strives to keep up to date with membrane technologies. Membrane developments are implemented within our system design. Staying ahead in this ever evolving field makes our RO units some of the most efficient on the market today.

Incoming Feed Pressure

Reverse osmosis water filters require a minimum pressure of 4 Bar. A system running below this figure will be extremely inefficient. A feed water pressure of between 6 to 8 Bar is the most efficient and least wasteful operational window for reverse osmosis.

Industrial Water Equipment use Grundfos pumps within the design of our industrial reverse osmosis filters. Grundfos are a highly respected manufacturer of water pumps and a trusted supplier. Using Grundfos within our range of RO’s ensures our filters are optimised for efficiency and maintain a stable operating pressure.

Water Source Impurities

Certain impurities within the feed water can result in a less efficient treatment process. A membrane(s) exposure to these impurities will lead to a reduction in productivity and an increase in waste water. Prolonged fouling of the membranes can also lead to the membrane(s) becoming permanently damaged and requiring replacement.

Different water sources contain different impurities. Pre filtration is designed to to optimise the efficiency of the RO membrane(s) by removing these impurities. This in turn leads to a reduction in the volume of waste water produced.

Feed Water Temperature

Lower feed water temperature leads to less efficient membranes and higher waste water production. The flow rates given on RO membranes are typically specified at an incoming feed water temperature of 77ºF. Temperatures lower than this result in more viscous water molecules which are therefore harder to push through the membrane(s).

In order to counteract the effects of colder water there are a number of measures which can be implemented. These include raising the pressure of the feed water or using low energy membrane(s).

Chemical dosing pump

The beauty of Reverse Osmosis is the relative lack of ongoing costs when compared to other competing water treatment technologies such as deionisation.

RO uses no chemical dosing and requires very little else in terms of maintenance. Typical costs involve replacement pre-filters as and when required. Then either cleaning or replacement of the membrane(s) when they begin to degrade.

Fouled reverse osmosis membrane

There are many factors that could potentially effect the longevity of the membrane(s). Unfortunately this means there is no one size fits all answer when asked how long does a membrane last.

As discussed in the previous questions, reverse osmosis membranes are sensitive to certain incoming water quality factors including :

- Water temperature

- Water pressure

- Level and quality of pre-filtration

- Volume of water being produced

- Level of contaminants

All of these can dramatically reduce a membranes lifespan. We would typically expect one of our reverse osmosis units to require replacement membrane(s) on average every 2 years.

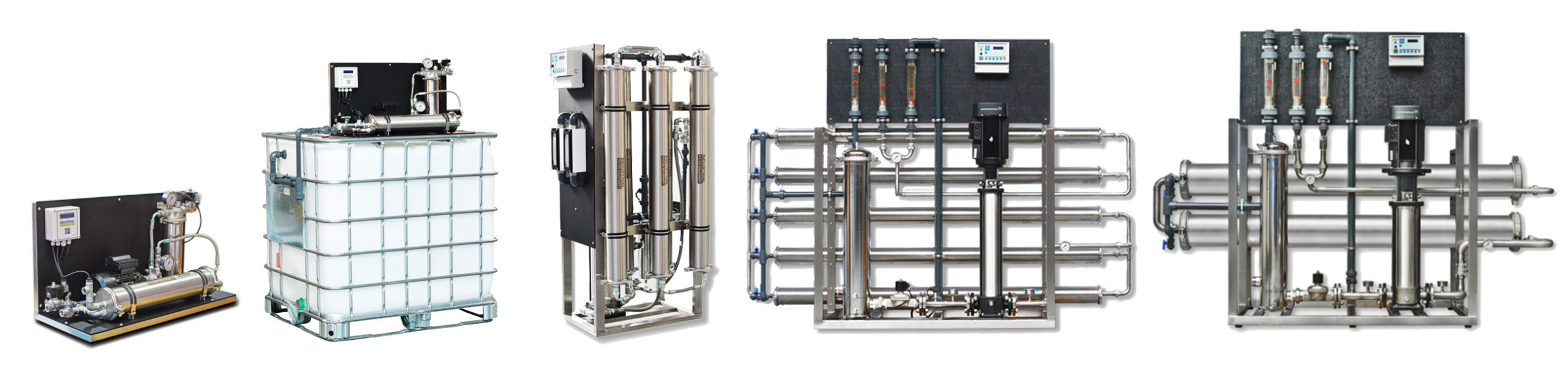

IWE Industrial Reverse Osmosis Range

We offer our standard ro units in 5 ranges :

IWE Compact : Flow rates up to 150 l/ph

IWE Compact IBC : Flow rates up to 150 l/ph

IWE Pro range : 300 to 1,500 l/ph

IWE Promax 4 range : 2,000 to 3,500 l/ph

IWE Promax 8 range : 4,300 to 12,000 l/ph

We feel our standard range covers the majority of industrial applications. For bespoke applications we have vast experience in developing systems to suit your exact requirements. Please contact us for further details.

Domestic Reverse Osmosis Range

For domestic reverse osmosis systems we offer two distinct ranges. Our traditional range is available in either pumped or un pumped variants with additional options for 4, 5 and 6 stages of filtration.

Each RO filter in our traditional range is complete with the following :

- A storage tank to house the filtered water

- A separate tap

- An installation kit

- Fitting instructions.

The Traditional un pumped requires a minimum of 3 Bar water pressure. The pumped version requires a minimum of 1.

Minimum pressure requirements for water suppliers within the UK is around 0.7 Bar. Always check your mains water pressure before making any purchase, especially if you’re considering the un pumped version of this RO unit.

Our Smart range of domestic reverse osmosis water filters are much more compact when compared to the Traditional range. Offering a more attractive ‘all in one’ design than their Traditional counterpart. Smart units are ofter installed on counter tops rather than under a counter.

The smart range again comes in either pumped or un pumped variations. A minimum pressure of 2 Bar for the electric or 3 Bar for the non electric version is required.

We are also able to supply a full range of spares for both the Traditional and Smart versions. These are available to purchase from our domestic reverse osmosis water filters page.

Our industrial range of filters have been developed, designed, tested and manufactured right here in the UK. Something which we are very proud of.

IWE are always striving to keep abreast of the latest technological advancements in the water treatment industry. We use the highest quality components throughout our range reverse osmosis filters.

Before leaving our warehouse each RO undergoes a full operational test at our testing facility. Each and every component is rigorously checked and tested before a final quality inspection check is undertaken prior being approved for dispatch.

Installation services

We can and often do install and commission reverse osmosis water filters. We employ a team of highly experienced and proficient engineers located across the whole of the UK. Each engineer covers all aspects of reverse osmosis and water treatment equipment installation.

We also offer range of service packages which can be taken out during any stage and on any type of water treatment plant. Our packages cover service work, breakdown calls, discounted spares and consumables, technical phone support and much more.

IWE’s service contracts are included in our Price Promise, whereby we guarantee to beat any like for like service contact by 20%. Please see our equipment servicing and maintenance page for further details.

So, whether you require installation on a newly purchased reverse osmosis water filter or servicing and maintenance on something else, we can help.

We have supplied and commissioned our filters to companies both large and small not only here in the UK but across the world.

Typical industries that we supply to include :

- Food and beverage production

- Breweries

- Distilleries

- Agricultural production

- Car manufacturers

- Car washes

- Beauty products

- Boiler and cooling tower production

- Chemical production

- Data centres

Reverse Osmosis Water Filters

Reverse Osmosis (RO) is an extremely effective method of removing unwanted contaminants from your water supply. Not only is RO an extremely safe method of filtration, it is also cost effective, requiring no chemicals and very little maintenance.

Our own new range of RO water filters, designed and developed at our Matlock branch in Derbyshire. Manufactured using only the highest quality components and featuring unbeatable recovery and efficiency.

We believe our range of RO drinking water filters are the most cost effective and efficient available on the market today.

Our range of RO filters are stocked and ready to be dispatched typically within a week from order. We also operate a testing facility where you are welcome to come along and view our range.