HOME | CARTRIDGE FILTERS & HOUSINGS | CINTROPUR FILTER HOUSINGS | INDUSTRIAL RANGE

industrial range

Cintropur Industrial Filters

For the protection of Industrial and Residential installations by filtering solid particles (earth, sand, rust etc) suspended in the water. The NW 500 TE is designed to be used with Activated Carbon for the improvement of taste and odour, chlorine, pesticide and other dissolved organic substance removal. All Cintropur Industrial Filters feature :

- Pressure Gauges :

0 to 20 bar, indicating system pressure and when filter sleeves need to be changed. - Centrifugal Vane :

Creating a cyclonic effect on the incoming water which precipitates larger particles to the bottom of the bowl. - Drain Valve :

For simple evacuation of impurities collected at the bottom of the bowl.

Industrial Applications – For the protection of sanitary fittings and machine tools.

Agricultural Applications – For filtration of water (spraying) installations. Filtration of water for animals, filtration of rainwater and well water.

Groups – (Hotels, Restaurants, Schools, buildings etc) – For protection of sanitary installations and all electrical / domestic appliances.

TECHNICAL DATA

| Filter type | NW 500 | NW 650 | NW 800 | NW 500 TE |

| Diameter of pipe | 2” | 2 1/2” | 3" | 2” |

| Average flow rate : m3/h | 18 | 25 | 32 | 2* |

| Working pressure : bar | 10 | 10 | 10 | 10 |

| Max. operating pressure : bar | 16 | 16 | 16 | 16 |

| Max. operating temp °C | 50° C | 50° C | 50° C | 50° C |

| Weight : Kg | 6.4 | 7 | 7.4 | 5.6 |

| Standard filter sleeve | 25 μ | 25 μ | 25 μ | - |

| Available volume : Ltr | - | - | - | 4.85 |

| Filtration Surface : | 1 288 | 1 288 | 1 288 | - |

ASSEMBLY INSTRUCTIONS

Possible applications

The range of water filters CINTROPUR® NW 500 – 650 – 800 is designed for filtering clear water with only low levels of substances in suspension, of the types town water, rainwater, borehole water, spring water. Other types of non-aggressive liquid can also be filtered. The possible areas of use will be in industrial, public and agricultural situations.

The materials used for making the filter are suitable for filtering liquid foods.

The use of the NW 500 TE with activated carbon is well known for dechlorination, removal of odours, improvement of taste, reduction of pesticides and herbicides.

Technical description

| NW 500 | NW 650 | NW 800 | NW 500TE | |

|---|---|---|---|---|

| Nominal connection diameter | 50 | 65 | 80 | 50 |

| For information | 2’’ | 2 ½’’ | 3’’ | 2’’ |

| Type of connection | External thread | Slip-on flange | Slip-on flange | External thread |

| Mean throughput (m³/h) with ΔP=0.2 bar | 18 | 25 | 32 | 2* |

| Mean throughput (m³/h) with ΔP=0.5 bar | 28 | 42 | 51 | 3.3* |

| Operating pressure (bar) | 10 | 10 | 10 | 10 |

| Max. working pressure (bar) | 16 | 16 | 16 | 16 |

| Working temperature | 30°C | 30°C | 30°C | 30°C |

| Maximum temperature | 50°C | 50°C | 50°C | 50°C |

| Weight (kg) | 6.4 | 7 | 7.4 | 5.6 |

| Filter screen | 25μ | 25μ | 25μ | - |

| Bowl volume | - | - | - | 4.85 l |

| Filter area (cm²) | 1288 | 1288 | 1288 | - |

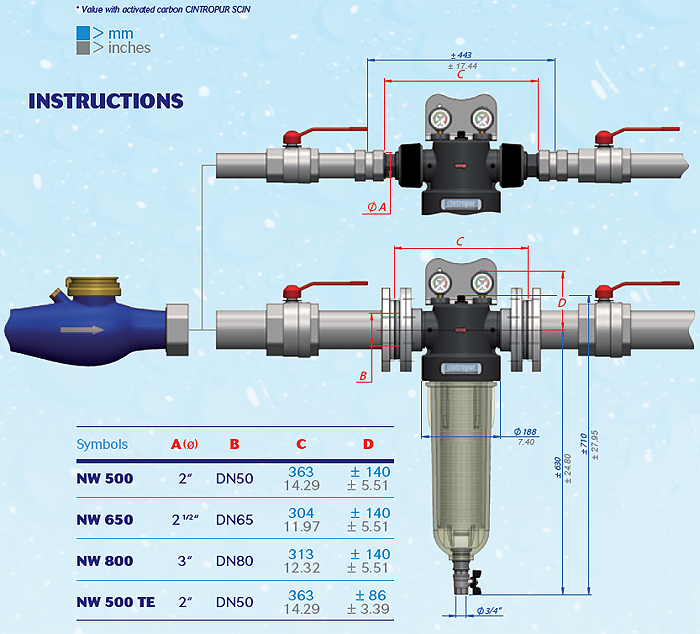

Assembly and handling

The ideal location for the CINTROPUR® water filter is directly at the plant inlet (after the meter or the pump). Ensure that the direction of water flow corresponds to the direction of the arrow on the filter head.

The filters must be fitted according to best practice: they must be free of mechanical stress, with the piping upstream and downstream aligned. The distance between the couplings or flanges must be correct to avoid causing any tension or compression stress on them.

A pressure reducer will effectively reduce the supply pressure if it exceeds the operating pressure. An anti-pressure surge device is indispensable if they occur in the installation.

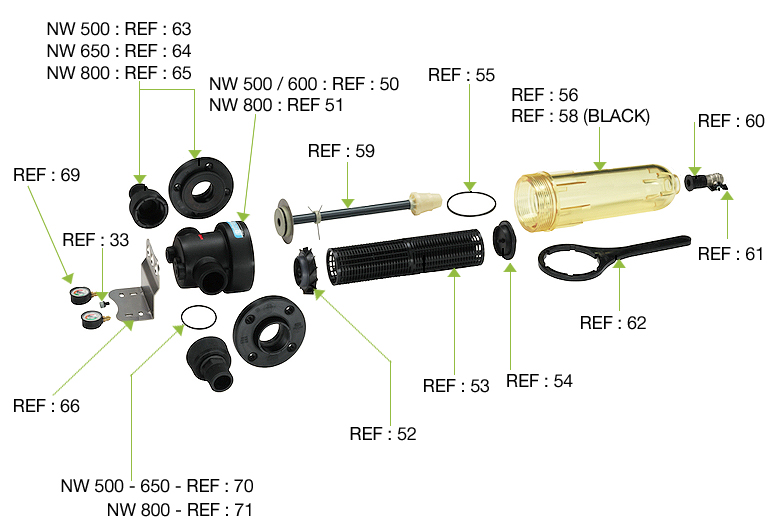

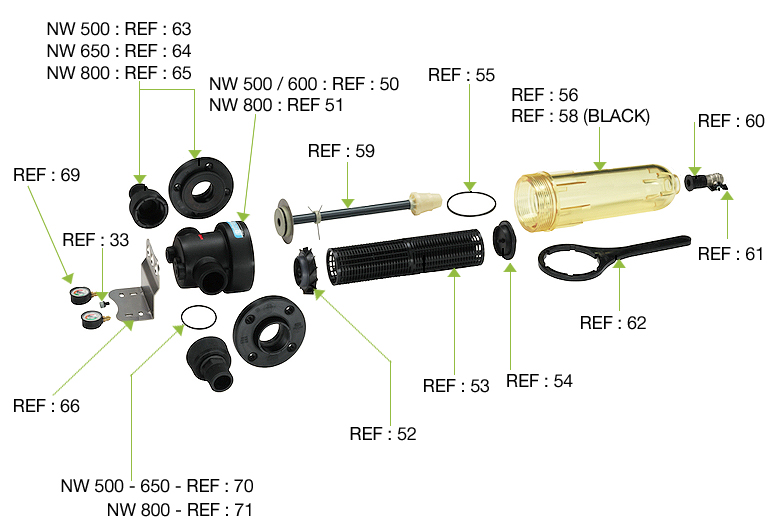

Equipment :

Standard: includes a set of 2 threaded connectors (NW 500 & 500TE) or a set of 2 slip-on flanges (NW 650 & NW 800), 2 pressure gauges (except the TE version), a 25μ filter screen fitted on its support, a purge valve and a spanner for disassembly.

The possible options are the opaque bowl, the stainless steel wall mount and the 2 flat sealing joints (for placing between the flange neck and the counter-flange).

The glycerine-filled pressure gauges supplied as standard (except on NW 500 TE) have a standard .’’ thread; fitting is done using a spanner (the dial is not to be used as a handle for screwing it in!).

Fixing the stainless steel wall mount to the filter head is done using the 2 thumbwheels provided for this purpose. For normal use, hand-tightening these is adequate for a good hold.

For the flanged filters NW650 and NW800:

The filter is supplied complete and ready to install

The flanges must be fitted off-axis (with the 2 upper holes in a horizontal line)

The flanges are compliant with DIN EN 1092-1 PN-10 with holes identical to EN 1092- 1 PN-16.

The flange of the NW650 requires 4 M16 bolts, and the flange of the NW800 requires

8 M16 bolts.

These bolts should be made moderately tight

NW650: flat seal for max. 10 bar 40 °C: 50 Nm.

NW650: profiled seal for max. 10 bar: 25 Nm.

NW800: flat seal for max. 10 bar 40 °C: 30 Nm.

NW800: profiled seal for max. 10 bar: 15 Nm

Water tightness between the flange of the CINTROPUR® NW 650 & 800 and the counter-flange of the installation must be provided by a flat seal of type EPDM-PN10 or EPDM-PN16 of good quality (as an option from CINTROPUR or available in the trade).

The original supplied couplings must be used because the metric thread of the head is not compatible with other standard couplings of the trade. They are of size M76x2,8 in type NW 500-650 and M88x2,8 in type NW 800.

For filters NW500

The union nuts to be screwed on are supplied separately in the packaging. When they are fitted it must be checked that the O-rings are present on the end pieces of the head where they will be screwed on.

The tightness of the threaded connections of the NW 500 can be achieved with any of the usual trade products. However, the hemp and paste from Kolmat is to be preferred. Leave one thread turn free on the filter connector to provide a good start for the valve or connector of your installation.

The original supplied couplings must be used because the metric thread of the head is not compatible with other standard couplings of the trade. They are of size M76 in type NW 500.

The tightness between the threaded connector and the filter head is ensured by a sealing ring; hand-tightening with two hands is sufficient for low pressures. For higher pressures, around 10 bar, tightening with a strap wrench is recommended. Checking the tightness is required when pressurising.

For filters NW500, 650 and 800

The tightness between the head and the bowl is ensured by an O-ring: tightening lightly with the supplied spanner is adequate. The spanner is also used for disassembly.

The purge valve adapter (in the lower part) is factory-fitted with a double sealing joint.

This adapter can rotate through 360° without damaging the bowl.

The cylindrical support of the filter screen is fitted at the 2 ends with a centrifugal spinner and a sealing cover. A holding screw fixes them to ensure complete sealing between the water to be filtered and the filtered water. A joint overmould has been implemented to this end. Handling of these fixing screws is done using only the hands (no tools).

Fitting isolating valves upstream and downstream is advised for assisting maintenance of the filter.

For the TE filter versions

Filling the bowl of the NW 500 TE with the treatment material (activated carbon, polyphosphate etc.) is made easier by following the rules stated in the appendix.

The models NW650TE & NW 800 TE do not exist as finished products; they can be made by replacing the internal filtration parts by the “tube + strainer” device.

Maintenance

Before disassembling the bowl, close the upstream and downstream valves and release the pressure.

Filter screen:

Maintenance and replacement of the filter screen used for drinking water is recommended at least 3 times per year and in any case before the pressure loss reaches 2 bar.

The filters graded 1, 5, 10, 25, 50 & 100 μ are intended for a single use. Cleaning them would change the structure of the fibre, so degrading the fineness of the selected filtering and making the filter more fragile, which could lead to tearing.

The nylon filters graded 150 & 300 μ are designed to be cleaned and re-used.

Activated carbon:

Replacement of the activated carbon in the NW 500 TE for drinking water is necessary every 90 m3 , and in other cases at least every 3 months.

Centrifugal spinner and cover:

The system for holding the centrifugal spinner on the cylindrical support is provided with 4 slots for correct positioning; take note of this before refitting.

Before refitting the sealing cover on the cylindrical support, ensure that the filter screen is not touching the cross of the internal reinforcement. Handle the fixing screws of the spinner and the cover only with bare hands (using a tool would cause damage).

The bowl:

The thread of the bowl must stay clean and greased for easy fitting and removal of the bowl during its life time.

The sealing ring between the head and the bowl must also remain clean and greased for good sealing.

All slots and O-ring seatings (& flat joint) must remain clean and without burrs.

Damaged component:

Every component of the filter, even if only slightly damaged, must be replaced immediately tO ensure good performance under pressure and water-tightness of the whole filter.

Warranty

The choice of high-quality raw materials for manufacturing each component of your filter is the best guarantee of giving you full satisfaction for many years of use. If, nevertheless, a component develops a fault related to a manufacturing defect, this would be covered by a replacement of that component under guarantee.