HOME | DEMINERALISATION | ION EXCHANGE DEMINERALISERS

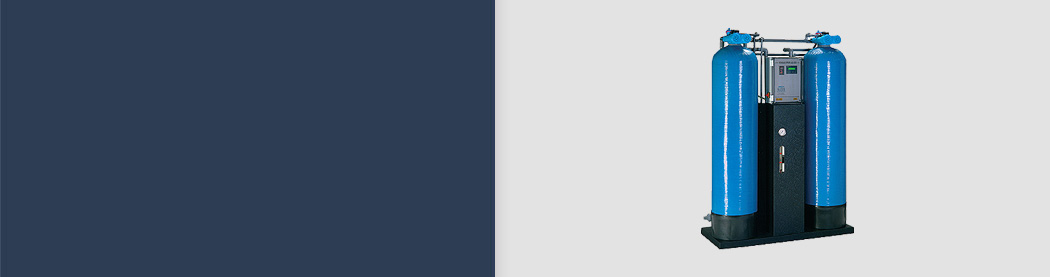

COMPACT DEMIN

Compact Demin

The IWE compact range of demineralisers are available in two sizes capable of flow rates up to 2500 litres per hour. Our demineralisers are a cost effective method of producing demineralised / deionised water with a typical conductivity of less than 25 micro siemens.

Features of IWE Compact Demineralisers

- Facia mounted message display provides user info stating operation modes and regen stage indication.

- Quality proven cation and anion are used giving optimum performance and reliability

- Manufactured from high quality corrosion proof materials

- Digital conductivity display with adjustable regeneration set point

- Fully integratable with onsite controls and available volt free contacts for alarms etc

- Duty standby configuration at no extra cost giving a unit capable of 24hr

Proflow DEMIN

Proflow Demin

The IWE Proflow range of demineralisers are available in various sizes capable of flow rates upto 25,000 litres per hour.

Our demineralisers are a cost effective method of producing demineralised / deionised water with a typical conductivity of less than 25 micro siemens.

Features of IWE Proflow Demineralisers

- Fully automatic regeneration cycle

- Stainless steel pumps and gauges

- Minimum moving parts ensuring maximum reliability

- Facia mounted message display provides user info stating operation modes and regen stage indication.

- Quality proven cation and anion are used giving optimum performance and reliability

- Manufactured from high quality corrosion proof materials

- Digital conductivity display with adjustable regeneration set point

- Fully intergratable with onsite controls and available volt free contacts for alarms etc

- Duty standby configuration at no extra cost giving a unit capable of 24hr service.

PROFLOW MAX DEMIN

Proflow Max Demin

The IWE Proflow Max range of demineralisers are available in various sizes capable of flow rates upto 25,000 litres per hour. Our demineralisers are a cost effective method of producing demineralised / deionised water with a typical conductivity of less than 5 micro siemens.

- Features of IWE Proflow Max Demineralisers

Fully automatic regeneration cycle - Stainless steel pumps and gauges

- Minimum moving parts ensuring maximum reliability

- Fascia mounted message display provides user info stating operation modes and regen stage indication.

- Quality proven cation and anion are used giving optimum performance and reliability

- Manufactured from high quality corrosion proof materials

- Digital conductivity display with adjustable regeneration set point

- Fully integratable with onsite controls and available volt free contacts for alarms etc

- Duty standby configuration at no extra cost giving a unit capable of 24hr service.

Counter Current DEMIN

Counter Current Demin

The IWE Counter Current range of demineralisers are available in various sizes capable of flow rates upto 20,000 litres per hour.

Our counter current demineralisers are a cost effective method of producing demineralised / deionised water with a typical conductivity of less than 0.5 micro siemens.

These units are specifically suitable as stand alone systems or for high quality polishing after such processes as reverse osmosis

Features of IWE Counter Current Demineralisers

- High quality water output

- Can be regenerated by capacity or conductivity

- Fully automatic regeneration cycle

- Stainless steel pumps and gauges

- Individual valve control

- Minimum moving parts ensuring maximum reliability

- Fascia mounted message display provides user info stating operation modes and regen stage indication.

- Quality proven cation and anion are used giving optimum performance and reliability

- Manufactured from high quality corrosion proof materials

- Digital conductivity display with adjustable regeneration set point

- Fully integratable with onsite controls and available volt free contacts for alarms etc

- Duty standby configuration at no extra cost giving a unit capable of 24hr service.

How does a demineralisation plant work

A Demineralisation water system always must consist of two usually GRP pressure vessels. One vessel contains cation resin and one vessel contains anion exchange resin.

There can be various types of cation and anion resins used but the selection is mainly down to the process and the incoming water quality. The usual anion and cation resins are Nuclear, weak or strong based ion exchange resins. On demineralisation systems other wise called demin systems or deionisation systems the cation ion exchange resin works in the hydrogen cycle. The cations present in the feed water ( calcium, sodium and magnesium) flow through the cation ion exchange resin where they are chemically exchanged for hydrogen ions (hence the term ion exchange).

The hydrogen rich feed water then flows through the anion ion exchange resin where the anions (i.e. bicarbonates, chlorides, nitrates, and sulphates) are exchanged for hydroxide ions. The feed water then only contains hydrogen ions and hydroxide ions, resulting in the composition of pure water H20.

Why are there different types of ion exchange resins used in our demineralisation plants?

The reason for using different resins in our deionisation equipment is as follows;

The quality of the treated water the demin system has to produce.

The quality of the feed water going into the demineralisation unit.

The temperature of the feed water

The flow rate of the demineralsation/deionisation equipment

If any organics are present within the feed water to the demin

If the demineralisation unit works counter-current or by co-current regeneration

All ion exchange resins for demineralisation or deionisation systems can be brought and viewed on our website please use side navigation.

How does a co-current regenerating demineralisation system work?

The ion exchange resin in the GRP Anion and cation pressure vessel has 50% free space above the ion exchange resin. This allows backwashing, removal of any particulates or solids, regeneration of the demin system resin bed and it relieves the ion exchange resin bed compaction.

Acid and caustic is drawn into the resin bed of the demin in a downwards direction

How does a demineralisation plant regenerate?

All Industrial Water Equipments demineralisation and deionisation systems regenerate automatically through conductivity readings taken via a conductivity probe intergral with the demin system.

How does mixed-bed demineralisation work?

Mixed bed demineralisation units are more commonly known as demin polishing units, The demin polisher will be installed after a single pass demineralisation system and will polish the treated water to a better quality or lower conductivity, these units have both anion and cation resins one vessel and are usually recharged by simply removing the resin and installing new within the cylinder.

Industrial Water Equipment also offer fully regenerable mixed bed demineralisation or deionisation units.

What quality of water can a demineralisation/deionisation unit produce.

A Cation column followed by an Anion column followed by a Polishing Mixed Bed demin system can expect to produce a water quality of less than 0.1 micro siemens.

A Cation column followed by an Anion column known as a Counter-Current demineralisation unit or deionisation unit can expect to produce between 0.5 to 1 micro siemens

A Cation column followed by an Anion column known as Co-Current demineralisation or deionisation system can expect to produce between 5 to 30 micro siemens.

All the above figures are very dependant upon water feed conditions and temperatures.

| Performance Chart | |||

| IWE COMPACT DEMIN | UNIT | COMPACT 30 | COMPACT 75 |

| MAX SERVICE FLOW | L/HR | 1500 | 2500 |

| WATER QUALITY AVERAGE | MICRO SIEMENS | 1/5/2015 | 1/5/2015 |

| CAUSTIC USAGE PER REGEN | LITRES | 11 | 20 |

| ACID USAGE PER REGEN | LITRES | 10 | 18 |

| REQ FEED WATER PRESSURE | BAR | 4 | 4 |

| Model Chart | ||||||

| MODEL | IWEC01-5 | IWEC02-5 | IWEC04 | IWEC06 | IWEC010 | IWEC020 |

| FLOW RATE l/h | 1500 | 2500 | 4000 | 6000 | 10000 | 20000 |

| WATER QUALITY | CONDUCTIVITY < 25 micro siemens typically 5-15 | |||||

| Model Chart | ||||||

|---|---|---|---|---|---|---|

| MODEL | IWECC1-5 | IWECC2-5 | IWECC4 | IWECC6 | IWECC10 | IWECC20 |

| FLOW RATE l/h | 1500 | 2500 | 4000 | 6000 | 10000 | 20000 |

| WATER QUALITY | CONDUCTIVITY < 5 micro siemens typically 2-3 | |||||

| Model Chart | |||||

| MODEL | IWECC2 | IWECC4 | IWECC6 | IWECC10 | IWECC20 |

| FLOW RATE l/r | 2000 L/HR | 4000 L/HR | 6000 L/HR | 10000 L/HR | 20000 L/HR |

| WATER QUALITY | RESISTIVITY >2M Ohm-cm. CONDUCTIVITY < 0.5 micro siemens | ||||

| Sizing Chart | |||

| IWE COMPACT DEMIN | UNIT | COMPACT 30 | IWECC4 |

| FEED WATER CONN | inches | 3/4" | 3/4" |

| TREATED WATER CONN | inches | 1/2" | 3/4" |

| DRAIN | inches | 1/2" | 3/4" |

| HEIGHT | mm | 1370 | 1630 |

| DEPTH | mm | 390 | 440 |

| WIDTH | mm | 835 | 985 |

| HEADROOM | mm | 1000 | 1000 |

| POWER | V | 240 | 240 |

| FUSE RATING | A | 3 | 3 |

| Sizing Chart | ||||||

| MODEL | IWEC01-5 | IWEC02-5 | IWEC04 | IWEC06 | IWEC010 | IWEC020 |

| I/L CONN | 3/4 BSP | 3/4 BSP | 1 BSP | 1 1/4 BSP | 1 1/2 BSP | 2 BSP |

| O/L CONN | 3/4 BSP | 3/4 BSP | 1 BSP | 1 1/4 BSP | 1 1/2 BSP | 2 BSP |

| DRAIN CONN | 1/2 BSP | 1/2 BSP | 1/2 BSP | 1 BSP | 1 1/4 BSP | 1/2 BSP |

| HEIGHT | 1377mm | 1560mm | 1835mm | 1775mm | 1985mm | 2628mm |

| DEPTH | 460mm | 515mm | 550mm | 720mm | 755mm | 1214mm |

| WIDTH | 985mm | 1140mm | 1300mm | 1540mm | 1745mm | 2628mm |

| HEADROOM | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| POWER | 1kw | 1kw | 1.3kw | 1.5kw | 2.3kw | 4kw |

| Sizing Chart | ||||||

|---|---|---|---|---|---|---|

| MODEL | IWECC1-5 | IWECC2-5 | IWECC4 | IWECC6 | IWECC10 | IWECC20 |

| I/L CONN | 3/4 BSP | 3/4 BSP | 1 BSP | 1 1/4 BSP | 1 1/2 BSP | 2 BSP |

| O/L CONN | 3/4 BSP | 3/4 BSP | 1 BSP | 1 1/4 BSP | 1 1/2 BSP | 2 BSP |

| DRAIN CONN | 1/2 BSP | 1/2 BSP | 1/2 BSP | 1 BSP | 1 1/4 BSP | 1/2 BSP |

| HEIGHT | 1377mm | 1560mm | 1835mm | 1775mm | 1985mm | 2628mm |

| DEPTH | 460mm | 515mm | 550mm | 720mm | 755mm | 1214mm |

| WIDTH | 985mm | 1140mm | 1300mm | 1540mm | 1745mm | 2628mm |

| HEADROOM | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| POWER | 1kw | 1kw | 1.3kw | 1.5kw | 2.3kw | 4kw |

Demineralisation Equipment

Industrial Water Equipment are the UK’s largest independent supplier of demin water and demineralisation equipment.

We have a full range of demineralisation equipment. Our standard range includes : Compact, Proflow, Proflow Max, Counter-Current and Bespoke Demineralisation systems.

We also offer a large range of cartridge exchange demin Units that can be used as Reverse osmosis polishing units, Demineralisation polishing units, TOC reduction and control, Trace metals removal, Ionic reduction, The removal of colour and odour and Chlorine reduction.