HOME | UV WATER FILTERS | INDUSTRIAL UV WATER FILTERS | CINTROPUR

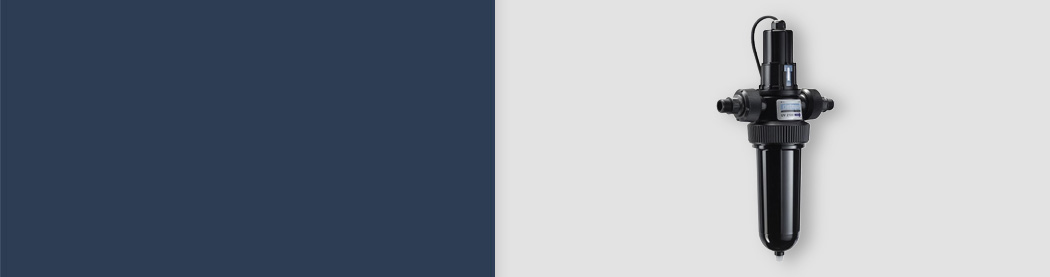

Cintropur UV Water Filters

- An environmentally friendly disinfection technology with a wide range of devices for UV sterilisation up to 10m3/hr.

- Extremely compact design with a unique bayonet light fitting.

- Innovative maintenance tracking system to know when to replace the lamp.

- Easy installation, use and maintenance.

- 100% physical disinfection without risk of overdose and without leaving any unpleasant taste or odour.

- No toxic by-products created in the process.

- Full compatibility with any CINTROPUR filter already fitted to the installation.

| Cintropur Specifications | ||||||

| Type of filter | 2000 | TIO-UV | 10000 | 2100 | DUO-UV | TRIO-UV |

| Connection diameter | 3/4" + 1" | 3/4" + 1" | 2" | 3/4" + 1" | 3/4" + 1" | 3/4" + 1" |

| Max flow rate (m3/hr) at 30ºC | 2 | 2 | 10 | 2 | 2 | 2 |

| Max working pressure (bar) | 16 | 16 | 16 | 16 | 16 | 16 |

| Max temperature | 50ºC | 50ºC | 50ºC | 50ºC | 50ºC | 50ºC |

| Weight (kg) | 4.1 | 6.2 | 7.6 | 1.7 | 2.8 | 4.3 |

| Water transmission (minimum %) | 90 | 90 | 90 | 90 | 90 | 90 |

| Lamp power (W) | 25 | 25 | 95 | 25 | 25 | 25 |

In order to guarantee that water is of drinkable quality, it must be chemically drinkable before being treated by UV.

The UV Cintropur is a 100% physical water treatment process using ultraviolet light to kill bacteria.

Water supplies can contain a large amount of harmless micro-organisms, but can also contain pathogenic varieties (faecal streptococci, faecal coliforms, sulphite-reducing bacteria, etc.).

These bacteria must be completely eliminated to make water potable.

The UV bulb emits luminous radiation with a maximum intensity at 253.7 nanometres. At this precise wavelength, pathogenic micro-organisms are totally eliminated, thus guaranteeing that the water is bacteriologically potable.

The UV Cintropur range of units may be used to treat water derived from a borehole, rainwater, runoff water or from a well that is contaminated with bacteria.

Design

The UV Cintropur is delivered with an ultraviolet bulb installed. The UV bulb is a low-pressure, mercury-vapour bulb, emitting light on the germicidal wavelength of 253.7 nanometres.

Installation

A flow limiter must be fitted to your UV steriliser (black plastic component packaged separately in a mini-grip bag). This flow limiter ensures that the maximum flow rate to be treated corresponds to the UV model that you have purchased. This flow limiter must ONLY be fitted if a Cintropur activated carbon filter is NOT installed (if a Cintropur activated carbon filter is installed, the flow rate is already sufficiently reduced and an additional flow limiter is not required).

The TIO-UV models are thus not fitted with a flow limiter since they are coupled with an activated carbon filter. The 10000 models are fitted with a flow limiter as standard.

The UV Cintropur is installed on the main water supply piping.

If the water treatment system on your installation comprises several treatment units, the UV is always installed as the final unit.

When the unit is first put into service, write the date of installation on the front of the electrical panel.

Make sure that there is enough room beneath the UV steriliser unit to withdraw and replace the lamp when it needs changing. It must be protected from frost.

We strongly recommend that a filter is installed upstream of the unit in order to reduce particulate matter than can mask the UV radiation.

To ensure maximum efficiency of the ultraviolet treatment, we recommend that the piping be subjected to shock disinfection.

During this operation, it is imperative that the UV Cintropur is switched off (furthermore, for the TIO-UV, the filter cartridge + activated carbon must be removed).

Disinfection of piping if there is a filter upstream of the UV Cintropur

– Remove the filter element from the filter unit;

– Fill the bowl with 50% hypochlorite solution 2 or 3 times;

– Run clean water through the piping until all traces of the taste and smell of hypochlorite have been removed;

– Refit the filter screen (and for the TIO-UV, replace the filter cartridge + activated carbon);

– Return the UV Cintropur to service.

We recommend that the piping be subjected to shock disinfection approximately once a year.

Electrical Connection

The electrical connection is made via a three-pin plug with earth (ground). Before connecting the unit, check that the power supply corresponds to the 220 volts, 50 Hz needed by the unit.

Operation

Before switching on the unit, check that there are no water leaks.

Fill the unit with water.

Switch on the unit.

When the UV bulb is operating a blue light can be seen through the transparent bowl.

The steriliser must always be left running, even if no water is being used. Nevertheless, in the event of a prolonged absence without any water being used (holidays, absence for longer than a week, etc.) the UV Cintropur should be switched off to avoid overheating of the transparent bowl and the UV bulb.

When service is resumed, allow the water to run for approximately 1 minute (with the steriliser switched on) before any is consumed.

Frequent Start/Stop operation (>5x/24 h) or operation without any water in the bowl is not recommended since the lifespan of the UV bulb will be reduced.

The UV Cintropur must only operate with water temperatures between 5°C and 50 °C; outside this range the unit may be damaged.

Safety Advice

Always switch off the bulb when carrying out maintenance operations on the unit. If the unit has to be checked while it is still operating, wear suitable eyewear (plastic glasses).

The UV Cintropur must only be used for the purposes for which it is intended. It must not be used to treat flow rates greater than the maximum stated flow rate (cf § 7 Technical data). A flow limiter is provided to ensure this (cf § 3 Installation). Safety and correct operation can only be guaranteed if the installation complies with the instructions in this document.

The treated water must not show any signs of colouration, nor contain any suspended matter; it must be chemically and physically potable.

Maintenance

Maintenance is limited to changing the UV bulb once a year on the same date, and to cleaning the quartz sheath if necessary.

When the unit is first installed, write down the date of installation on the front of the electrical panel (cross off the year and month).

Cross off the corresponding month and year each time the bulb is changed.

Switch off the UV CINTROPUR before carrying out any maintenance work on the unit.

For the TIO-UV, we recommend renewing:

The filter sleeve at least 2x / year;

The activated carbon charge in the cartridge container at least 2x / year. The lid of the container can be unscrewed; to reduce maintenance costs, just replace the activated carbon while keeping the cartridge container

In order to keep your TIO working good, make sure that the excess part of the sleeve is placed on the bottom lid side and not under the strainer of the container.

UV Bulb

The UV bulb has a lifespan limited to 9,000 hours, after which disinfection of the water can no longer be assured. The bulb must be changed:

At least once a year;

Or when it ceases to operate (blue light no longer visible). If this should occur, the warning buzzer will sound to warn of the failure.

The quartz sheath protecting the bulb ensures that changing the bulb is greatly simplified: the UV Cintropur does not need to be either drained or dismantled.

Unplug the unit from the power supply;

Slacken off the retaining cap on the electrical cable;

Unscrew and remove the plug;

Hold the bulb to prevent it falling out;

Disconnect the 2 white connecters from the bulb.

Installing the new bulb

The new, UV bulb must be perfectly dry before it is fitted to the quartz sheath. Take great care to ensure that your fingers do not come into contact with the glass of the bulb. You should wear cotton gloves, or use a cloth. The bulb may be cleaned with alcohol to remove any traces of finger marks.

Reconnect the two electrical connectors, which were previously removed, to the pins on the new bulb.

Reposition the new bulb in the quartz sheath taking particular care to ensure that the 2 wires are not twisted. Check this by gently pulling on the 2 wires once the bulb has been replaced in the quartz sheath.

Insert the bulb in the quartz sheath taking care to ensure that it is pushed right home to the end of the quartz sheath.

Screw the plug back into position and tighten down the retaining cap on the electrical cable.

Note: As for fluorescent tubes, defective UV bulbs must be disposed of in accordance with national regulations, or at an approved waste-disposal site. They must not be disposed of with standard domestic or industrial waste (the bulb contains particles of mercury).

Quartz sheath

The quartz sheath may clog up or show signs of traces of lime scale. Should this occur, the sheath must be removed and cleaned using dilute acid (hydrochloric acid, vinegar, lime scale solution). Any product that is used must not be abrasive.

Before carrying out any maintenance, the water supply to the unit must be turned off and the unit must be drained.

Unplug the electrical power supply cable;

Turn off the water supply and release all pressure;

Dismantle and remove the UV bulb as detailed previously;

Position a bucket beneath the UV Cintropur unit and unscrew the seal support of the sheath. Remove the sheath;

Sealing for the sheath within the seal support is ensured by means of 2 O-rings;

Check the condition of the O-rings and replace them if necessary;

Remove the seal support sheath;

Clean it using a gentle acid without the use of any abrasive;

Rinse it, dry it and reassemble it in the seal support into which the 2 O-rings have already been fitted;

Screw down the seal support;

Reinstall the UV bulb;

Reconnect the water supply to the UV Cintropur;

If no leaks are observed, switch the steriliser back on.

Shock disinfection

It is recommended that the piping system in the house be disinfected once a year.

Failures / Fault Detection

FAILURE POSSIBLE CAUSE CORRECTIVE ACTION

The UV bulb does not light up The bulb is not connected correctly Check connection of the

2 connectors

The bulb is worn out or faulty Replace the bulb

The unit is not connected Connect the power supply cable

One of the electrical components is faulty (ballast, starter) Contact your installer

or the After Sales Service

Water leaks from the unit Leak at the sheath seal support Hand tighten the seal support or change the 2 O-rings inside

Guarantee

Based on your invoice, your UV filter will be guaranteed for 2 years. As the starter, the quartz and the lamp are considered consumables, they are not covered by this guarantee.

Every use or installation which does not comply with the installation instructions is excluded from the present guarantee.

Yes, you can. These are designed to be upgraded at a later date, so please get in touch with one of our engineers and they can advise the best course of action.

To ensure that you are protected and are receiving disinfected water, you are required to replace the lamp every twelve months and as a minimum the filter should also be replaced every twelve months. The filter depending on the incoming quality may require changing more frequently.

We keep all of the lamps, quartz sleeves, ballasts in stock for when you require them.

UV Water Filters

The Cintropur UV Water Filter range has a capacity from 1 to 10 m3/h. The UV’s are more compact than any other UV-device with a built-in flow reducer which guarantees optimal treatment.

Cintropur UV’s are ideal for applications such as : baths and showers, food preparation, aquariums and drinking water for livestock.