HOME | REVERSE OSMOSIS | INDUSTRIAL REVERSE OSMOSIS | HERCO | BUDGET RANGE

HERCO Budget RANGE

| Tech Data | UO | Budget 80 |

| Permeate flow rate | l/h | 80 |

| Min. salt rejection | % | 95 |

| Recovery | % | 50 |

| Operating pressure | bar | 10.0 |

| Membrane element / number | 2540/1 | |

| Voltage | V/Hz | 230/50 |

| Motor power | kW | 0.4 |

| Pre-fusing | A | 16 |

| Feedwater connection | R | ¾'' AG |

| Permeate/concentrate connection | DN | 10 |

| Conductivity range | μS/cm | 1 – 99 |

| Min. / max. feed water pressure | bar | 3 / 6 |

| Min. / max. feed water temp | °C | 5 / 35 |

| Max. ambient temperature | °C | 40 |

| pH | 3 – 11 | |

| Height | mm | 370 |

| Width | mm | 800 |

| Depth | mm | 370 |

| Weight approx | ca. kg | 31 |

| Code no | 381 900 |

| Tech Data | UO | Budget 130 |

| Permeate flow rate | l/h | 130 |

| Min. salt rejection | % | 95 |

| Recovery | % | 50 |

| Operating pressure | bar | 10.0 |

| Membrane element / number | 4021/1 | |

| Voltage | V/Hz | 230/50 |

| Motor power | kW | 0.4 |

| Pre-fusing | A | 16 |

| Feedwater connection | R | ¾'' AG |

| Permeate/concentrate connection | DN | 10 |

| Conductivity range | μS/cm | 1 – 99 |

| Min. / max. feed water pressure | bar | 3 / 6 |

| Min. / max. feed water temp | °C | 5 / 35 |

| Max. ambient temperature | °C | 40 |

| pH | 3 – 11 | |

| Height | mm | 370 |

| Width | mm | 800 |

| Depth | mm | 370 |

| Weight approx | ca. kg | 31 |

| Code no | 381 901 |

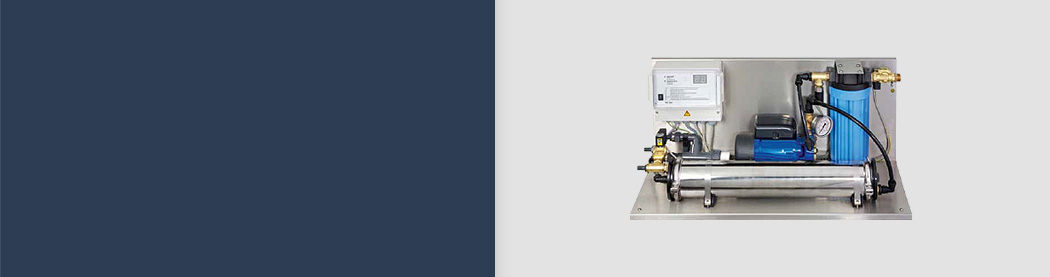

Description

Stainless steel plate used as installation panel housing the instruments and controls. Special inlet filter with 5 μm activated carbon filter element, high pressure pump, high performance spirally wound module with PA/PS composite membranes in stainless steel pressure vessel. Valves and instruments including solenoid inlet valve, feed water pressure switch, vibration-resistant pressure gauge for pump pressure, flow restrictor for limitation of permeate and concentrate flow rate. Solenoid valve, Microprocessor control system as described below, connecting cable (2 m) with shockproof plug. Unit completely wired and pre-assembled and ready for installation. Electrical equipment in accordance with VDE 0100 part 600, VDE 113 part 1.

RO 524 microprocessor control system

For fully automated monitoring and control of the reverse osmosis unit with two-digit alphanumeric display of permeate conductivity*, forced stop and full tank, malfunction signals: low pressure, hard water and high conductivity*,automatic restart of operation after progressive rest period, LEDs for operation and disinfection, concentrate flushing each operating cycle, forced flushing after 24 h standby Additional connections possible: Inputs (low voltage) for level control with 1 or 2 float switches, hardness monitoring unit (the RO 524 controller includes control functions for the limitron hardness monitoring unit), shut-downs by external signal (forced stop, regeneration). Outputs for softening unit (230 V / 50 Hz) and DDC (collective malfunction signal on floating change-over contact). The units are designed for a maximum TDS of 1,000 mg/l, a water temperature of 15°C, a max. colloidal index of 3 an free permeate outlet. Under these conditions, the unit reaches design permeate flow. The permeate recovery depends on the raw water quality and the type of pre-treatment.

Herco Budget Range

Under sink unit for desalination of softened drinking water according to German drinking water regulations (free chlorine not detectable), operating on the principle of reverse osmosis.

Drinking water can also be desalinated without pre-treatment. However, in this case the recovery rate is reduced. The decisive factor is the water analysis.