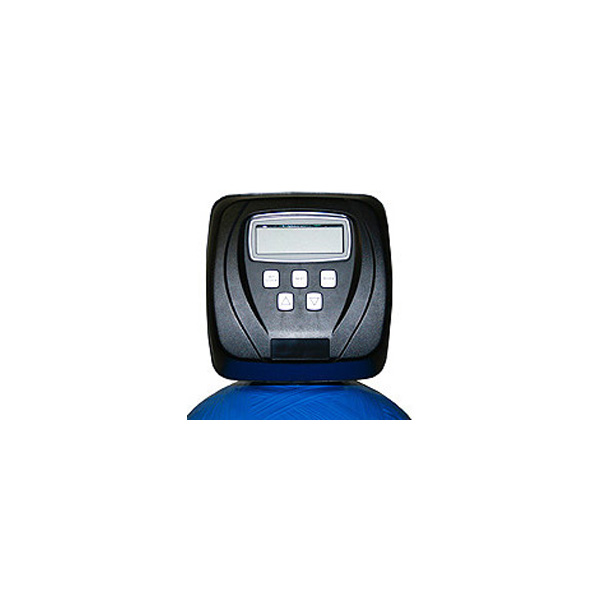

Clack Activated Carbon Water Filter – 0.89 m3/hr

£491.38 - £589.65 (inc. VAT)

Activated carbon water filters are highly effective in water treatment due to their unique adsorption properties. When used to treat water, activated carbon plays a crucial role in removing various impurities, contaminants, and unwanted substances.

Chemical Adsorption: Activated carbon possesses a large surface area with numerous microscopic pores. This extensive surface area allows it to attract and capture molecules and particles from water through a process called adsorption. As water flows over or through the activated carbon, it acts like a sponge, trapping impurities within its porous structure.

Removal of Organic Compounds: Activated carbon is particularly efficient at removing organic compounds from water. This includes contaminants like chlorine, volatile organic compounds (VOCs), pesticides, and various chemicals. These compounds are drawn into the carbon’s pores, effectively reducing their concentration in the water.

Taste and Odour Removal: Activated carbon is highly effective in improving the taste and odour of water. It can remove unpleasant tastes and smells often associated with chlorine, sulphides, and other organic substances.

Colour Reduction: In cases where water has a yellow or brownish tint due to dissolved organic matter, activated carbon can be used to reduce the colour, making the water appear clearer.

Chlorine Removal: Activated carbon is a common component in water filters for the removal of chlorine and its byproducts, such as chloramines. This is especially important for improving the taste of drinking water and protecting household appliances like coffee makers and water heaters.

Contaminant Removal: Activated carbon can remove a variety of contaminants, including heavy metals like lead and mercury, as well as some microorganisms and bacteria. However, it may not be as effective at removing certain inorganic compounds or salts.

Filter Bed for Other Treatments: Activated carbon is often used as a pre-treatment step in water purification processes. It can serve as a filter bed to remove larger particles and reduce the load on downstream treatment processes like reverse osmosis or UV disinfection.

Clack Activated Carbon Filters Key Information

| Ref | Description | Control Valve | Tank Size | *Media Volume in bags | **Flow Rate |

| AC20-C1 | 0.62 m3/hr Activated Carbon WS1 System | Clack WS1 | 10” x 54” | 0.8 | 0.62 m3/hr |

| AC25-C1 | 0.89 m3/hr Activated Carbon WS1 System | Clack WS1 | 12” x 52” | 1.0 | 0.89 m3/hr |

| AC35-C1 | 1.05 m3/hr Activated Carbon WS1 System | Clack WS1 | 13” x 54” | 1.4 | 1.05 m3/hr |

| AC50-C1 | 1.21 m3/hr Activated Carbon WS1 System | Clack WS1 | 14” x 65” | 2.0 | 1.21 m3/hr |

| AC63-C1 | 1.59 m3/hr Activated Carbon WS1 System | Clack WS1 | 16” x 65” | 2.5 | 1.59 m3/hr |

| AC85-C1 | 2.0 m3/hr Activated Carbon WS1 System | Clack WS1 | 18” x 65” | 3.5 | 2.0 m3/hr |

| AC100-C1 | 2.73 m3/hr Activated Carbon WS1 System | Clack WS1 | 21” x 60” | 4.0 | 2.73 m3/hr |

| AC150-C15 | 3.57 m3/hr Activated Carbon WS1.5 System | Clack WS1 | 24” x 69” | 6.0 | 3.57 m3/hr |

| AC200-C15 | 5.57 m3/hr Activated Carbon WS1.5 System | Clack WS1.5 | 30” x 72” | 8.0 | 5.57 m3/hr |

| AC300-C2 | 8.02 m3/hr Activated Carbon WS2 System | Clack WS2 | 36” x 72” | 12.0 | 8.02 m3/hr |

| AC450-C2 | 10.92 m3/hr Activated Carbon WS2H System | Clack WS2H | 42” x 78” | 18.0 | 10.92 m3/hr |

| AC550-C3 | 14.26 m3/hr Activated Carbon WS3 System | Clack WS3 | 48” x 82” | 22.0 | 14.26m3/hr |

| *Activated Carbon contains 50L per bag and equates to 25kg per bag | Based on a contact time of five minutes | |||||

| ** Flow rates based on a five 5 gpm / sqft for ordinary taste, odour and chlorine loads with freeboard of 30% | |||||