HOME | WASTEWATER & RECYCLING | PACKAGED SYSTEMS | CLEARFOX SBR

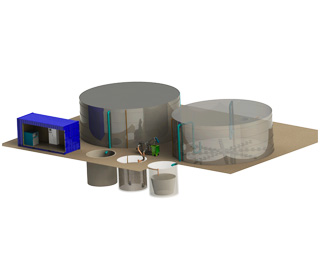

SBR equipment in kit form to install into any tank configuration (above or below ground)

SBR equipment in kit form to install into any tank configuration (above or below ground)- Can be installed in tanks with 1, 2 or 3 chambers of any shape (subject to minimum volumes)

- Systems can be installed in Concrete / GRP / Plastic tanks

- Retrofitting kits can also be installed into existing tanks for upgrade works

- Kits designed for large projects (no limits)

- Simple installation requires no previous experience as kits are preassembled

- A low cost, high quality solution for tank manufacturers

- Suitable for the treatment of domestic, municipal and industrial wastewaters

- Kits designed also for large projects (up to 15.000 p.e.)

- Complete support from ClearFox® for engineering, design and installation

- Airlift or submersible pump options depending on discharge / population are delivered

- SBR is a controlled process as wastewater is treated in batches – allowing for extremely high effluent quality

- Any effluent standard can be achieved with additional chemical dosing (e.g. P elimination), UV treatment (disinfection) etc. all easily added via the PLC

- Process control allows to achieve any required effluent quality with nitrification, denitrification, P reduction, UV disinfection etc.

- Designed according to DIN EN 12566-3 and DWA design criteria

- Market leading in treatment efficiency and low power consumption

- Simple modification of the process via PLC if necessary

- Lower OPEX than many traditional processes (such as MBBR and other technologies)

- Easily transportable SBR equipment kits in comparison to fixed film equipment

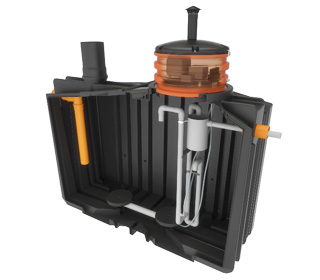

ClearFox® SBR Standard

The domestic treatment system for 4 up to 50 PE

• Small sewage treatment plants for modular construction

• The highest individual weight is 115 kg

• No crane is required on the building site

• Continuous and worry-free operation

• Simple and fast assembly

• Fully automatic operation

The SBR system works with activated sludge, but when compared to standard extended aeration systems the efficiency is much higher, due to the equalised peak flow.

How your SBR sewage treatment plant is delivered

The ClearFox® SBR small sewage treatment plant is fully biological and ready to connect. It is a compact, modular sewage treatment plant with high quality, clog-free airlift-pumps. The system has an integrated energy-saving mode and monitors overfilling with fully automatic pressure measurement.

The ClearFox® SBR small sewage treatment plant is fully biological and ready to connect. It is a compact, modular sewage treatment plant with high quality, clog-free airlift-pumps. The system has an integrated energy-saving mode and monitors overfilling with fully automatic pressure measurement.

No calibration is required, as the system does this automatically. The system has an air manifold with high quality and noise-free actuators. The hose connections are made of high quality stainless steel ensuring reliability, as these do not break.

The complete control unit is integrated into the ventilated manhole pit, which saves laying cables etc. Only an inlet, outlet and a power cable (earth cable 3×1,5mm2) must be connected and no further connection work is required! The inlet and outlet openings are prepared for KG DN100 (high-quality EPDM-gaskets are already integrated in the tank).

The monolith tanks are made of high-quality PE. They are manufactured by rotational moulding, which produces a one piece seamless tank without additional work required (as would a screw-connected tank on the contrary). The vertically positioned rib structure of the tank ensures stability, as well as good and ergonomic blending in the reactor. The tanks are equipped with additional internal stainless steel reinforcements.

In their basic configuration the tanks are equipped with a manhole pit extension for an inlet depth of ~78 cm. The tank covers (load-bearing up to 200 kg) are screw-tightened (childproof version). The plant is CE conform and includes DIN EN 12566-3 test certificates for efficiency, water-tightness and fracture resistance. The plant consists of two interconnected tanks which can be placed into the building pit as one piece.

All technical components of the plant are pre-assembled in the factory and are ready to be connected (plug and play).

- 1 PE container 1250 liters, (biology reactor) Single weight: ~ 105 kg (including control module) Dimensions: l/w/h 89.5 x 121.5 x 230 cm

- 1 PE container 2250 liters, (primary treatment and buffer) Single weight: ~ 125 kg Dimensions : l/w/h 153.5 x 121.5 x 230 cm

- Required base: ~ 245 x 122 cm

- Max. Supply depth: 100 cm below ground level

- Eentry opening Container: 60 cm

- Duct shaft extension: Inlet depth ~ 78 cm (shaft length 60 cm)

- Power supply: Ground cable laid with 230 VAC, 3 x 1,5mm², fuse 10A, RCCB

- Control module integrated in the dome shaft of biology

- Connected load: ~ 80W

- Plant size: 6 PE (people equivalent)

- Waste class: C and D (according to German classification)

- DIBt approval no. Z-55.31-419, Class C

- DIBt Approval Number. Z-55.31-418, Class D

Additional options for SBR:

- The inflow depth can be extended by replacing a longer Wavin Tegra DN 600 pipe (provided by customer)

- Anti-lift protection according to the installation instructions

-

1 PE container 2250 liters, (biology reactor) Single weight: ~ 145 kg (incl. Control module) Dimensions: l/w/h 153.5 x 121.5 x 230 cm

-

1 PE container 2250 liters, (primary treatment and buffer) Single weight: ~ 125 kg Dimensions : l/w/h 153.5 x 121.5 x 230 cm

-

Required base: ~ 308 x 122 cm

-

Max. Supply depth: 100 cm below ground level

-

Entry opening Container: 60 cm

-

Duct shaft extension: Inlet depth ~ 78 cm (shaft length 60 cm)

-

Power supply: Ground cable laid with 230 VAC, 3 x 1,5mm², fuse 10A, RCCB

-

Control module integrated in the dome shaft of biology

-

Connected load: ~ 80W

-

Plant size: 6 PE (people equivalent)

-

Waste class: C and D (according to German classification)

-

DIBt approval no. Z-55.31-419, Class C

-

DIBt Approval Number. Z-55.31-418, Class D

Additional options for SBR:

-

The inflow depth can be extended by replacing a longer Wavin Tegra DN 600 pipe (provided by customer)

-

Anti-lift protection according to the installation instructions

- 1 PE container 2250 liters, (biology reactor) Single weight: ~ 145 kg (incl. Control module) Dimensions: l/w/h 153.5 x 121.5 x 230 cm

- 1 PE container 2250 liters, (primary treatment and buffer) Single weight: ~ 125 kg Dimensions : l/w/h 153.5 x 121.5 x 230 cm

- 1 PE container 1250 liters, (primary clarification) Single weight: ~ 80 kg Dimensions: l/w/h 89.5 x 121.5 x 230 cm

- Required base: ~ 398 x 122 cm

- Max. Supply depth: 100 cm below ground level

- Entry opening Container: 60 cm

- Duct shaft extension: Inlet depth ~ 78 cm (shaft length 60 cm)

- Power supply: Ground cable laid with 230 VAC, 3 x 1,5mm², fuse 10A, RCCB

- Control module integrated in the dome shaft of biology

- Connected load: ~ 80W

- Plant size: 8 PE (people equivalent)

- Waste class: C and D (according to German classification)

- DIBt approval no. Z-55.31-419, Class C

- DIBt Approval Number. Z-55.31-418, Class D

Additional options for SBR:

- The inflow depth can be extended by replacing a longer Wavin Tegra DN 600 pipe (provided by customer)

- Anti-lift protection according to the installation instructions

- 1 PE container 2250 liters, (biology reactor) Single weight: ~ 145 kg (incl. Control module) Dimensions: l/w/h 153.5 x 121.5 x 230 cm

- 1 PE container 2250 liters, (primary treatment and buffer) Single weight: ~ 125 kg Dimensions : l/w/h 153.5 x 121.5 x 230 cm

- 1 PE container 2250 liters, (primary clarification) Single weight: ~ 80 kg Dimensions: l/w/h 153.5 x 121.5 x 230 cm

- Required base: ~ 462 x 122 cm

- Max. Supply depth: 100 cm below ground level

- Entry opening Container: 60 cm

- Duct shaft extension: Inlet depth ~ 78 cm (shaft length 60 cm)

- Power supply: Ground cable laid with 230 VAC, 3 x 1,5mm², fuse 10A, RCCB

- Control module integrated in the dome shaft of biology

- Connected load: ~ 120W

- Plant size: 10 PE (people equivalent)

- Waste class: C and D (according to German classification)

- DIBt approval no. Z-55.31-419, Class C

- DIBt Approval Number. Z-55.31-418, Class D

Additional options for SBR:

- The inflow depth can be extended by replacing a longer Wavin Tegra DN 600 pipe (provided by customer)

- Anti-lift protection according to the installation instructions

ClearFox® SBR QuickONE+

QuickONE+, the ClearFox® single chamber SBR

QuickONE+ single chamber SBR system, plug & play, odour free, with whisper quiet operation.

Highest effluent quality and lowest energy consumption on the market, as a new plant or to retrofit existing systems.

Manufactured in: Germany

Retrofitting: Yes, as a kit system to install in your existing tank.

Send your septic tank dimensions and we will configure a retrofitting kit that suits.

Special features QuickOne+:

-

Bestseller in Europe

-

Market leading effluent quality

-

Lowest energy consumption on the market

-

Odour free and whisper quiet operation

-

Does not run constantly, resulting in very small power consumption relative to standard systems

-

Extended desludging intervals due to sludge stabilisation

-

No moving parts in the tank

-

Entire process powered by a small air compressor (60 watt)

-

30% less sludge production than competitor systems

-

Very low running and maintenance costs

-

Shallow dig tanks for easy installation (1420mm from base of tank to base of inlet)

-

Robust and easy to maintain

-

Stainless steel reinforcement internally

-

Designed for easy export in 40ft containers

QuickOne+ Function

The Clearfox® QuickONE+ is one of our most popular small scale sewage treatment systems and for good reason. It produces the best effluent quality on the market but with the lowest energy consumption of any sewage system available. We can prove this with our CE declaration independent test certificate and the DIN EN12566-3 test. It meets local and national wastewater rules and regulations. The ClearFox® QuickONE+ is a pre-assembled small wastewater treatment plant made of stainless steel reinforced polyethylene. The control module and housing is integrated in the (ventilated) manhole shaft above the biology chamber. For installation, only the inlet, outlet and a power cable needs to be connected.

The biology chamber and sampling point are easily accessed by the manhole. Maintenance is simple, as there are no moving parts and installation errors are avoided as it is plug & play.

How does a Clearfox SBR Wastewater plant function?

SBR refers to sequential batch reactor. This technology is a controlled wastewater treatment process. Batches of wastewater undergo treatment in sequence. This control process allows each batch of wastewater to undergo treatment for any required time frame. This enables the achievement of any level of treatment as a result.

In brief, the typical steps in the SBR process are as follows:

The activated sludge treatment plant with SBR has an upstream coarse separator that serves as storage for the primary and secondary sludge and to buffer the inlet water. Sludge filling and Clearwater extraction are effected by means of airlift pumps. The plants control system recognises four main states in the Normal cycle.

- Filling phase: the sewage enters the first chamber and any large solids are retained. The filling pump then conveys waste water into the second chamber which is the biological reactor.

- Purification/Aeration stage: The waste water is circulated in the SBR reactor using air fed by the membrane plates and the bacteria are supplied with oxygen, thus supporting the actual biological treatment by microorganisms. Short aeration and non-aeration stages (for denitrification) alternate and are controlled by the computer software. An activated sludge grows with millions of microorganisms which completely break down the wastewater.

- Sedimentation/settling stage: A rest phase follows. The activated sludge sinks (sedimentation) to the bottom of the water column. This allows a clarified water zone to form at the top of the reactor chamber.

- Clearwater extraction stage: A Clearwater pump conveys the purified waste water that remains above the “Clearwater discharge point” to the plant outlet, lowering the water level in the reactor. The settled activated sludge is then transferred back into the first chamber and the process repeats with the next batch of wastewater.

A complete purification cycle takes approximately 7 hours

Energy-saving cycle: The purification cycle programme continues running unabated, but with a shorter aeration phase, which reduces the amount of energy required. Depending on the inlet quantity to the prechamber, the programme then decides fully automatically, whether the energy- saving cycle should continue, or whether it should switch back to normal operating mode.

Contact us for a free quotation

Do you have a question or need more information about a sewage treatment plant? We shall be happy to develop a suitable solution to your specific requirements.

Please call us on 01629 363311 or use the form below.

CONTACT US

Wastewater Packaged Systems

Sewage treatment systems pre-assembled at the factory and tested according to the European standard 12566-3 and 12566-6.

SBR equipment in kit form to install into any tank configuration (above or below ground)

SBR equipment in kit form to install into any tank configuration (above or below ground)